News

Digital Twins: How Virtual Engineering Is Revolutionizing the Automotive Industry

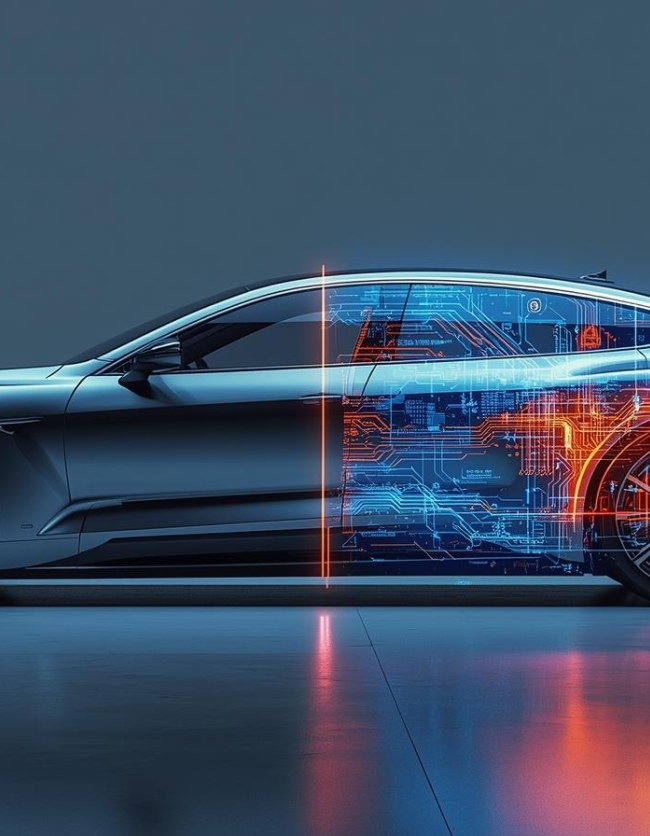

Digital twins are changing the way automotive engineering develops new products. With them, it is possible to create virtual replicas of vehicles and components, enabling advanced simulations that anticipate failures, optimize processes, and make production more efficient.

What are digital twins?

Digital twins are virtual models that replicate, in detail, the behavior of a physical product. In the automotive sector, this technology makes it possible to analyze everything from the durability of parts to the performance of complex systems, without the need to build multiple prototypes.

Applications in the automotive industry

• Durability and reliability testing: simulations that reproduce years of use in just weeks.

• Optimization of fuel consumption and energy efficiency: performance analysis in different scenarios.

• Noise and vibration reduction (NVH): adjustments before the vehicle reaches the track.

• Crash and safety simulations: digital evaluations that increase product reliability.

Strategic benefits for automakers

In addition to reducing costs with physical prototypes, digital twins enable faster product launches, with lower risk of failure and greater consumer confidence. It is a competitive advantage for companies looking to accelerate their presence in the global market.

Global Group’s expertise

At Global, we apply digital twins in automotive projects with a focus on innovation, safety, and efficiency. Our engineering team works closely with automakers and suppliers to transform data into strategic decisions that ensure more reliable and sustainable vehicles.

Digital twins represent one of the greatest innovations in the automotive industry, combining technology, efficiency, and precision. Do you want to apply this technology to your projects and accelerate innovation? Contact Global Group and discover how to transform the virtual into real-world results.